Table of Contents

What is PDCA? – A Step-by-Step Explanation of the Process

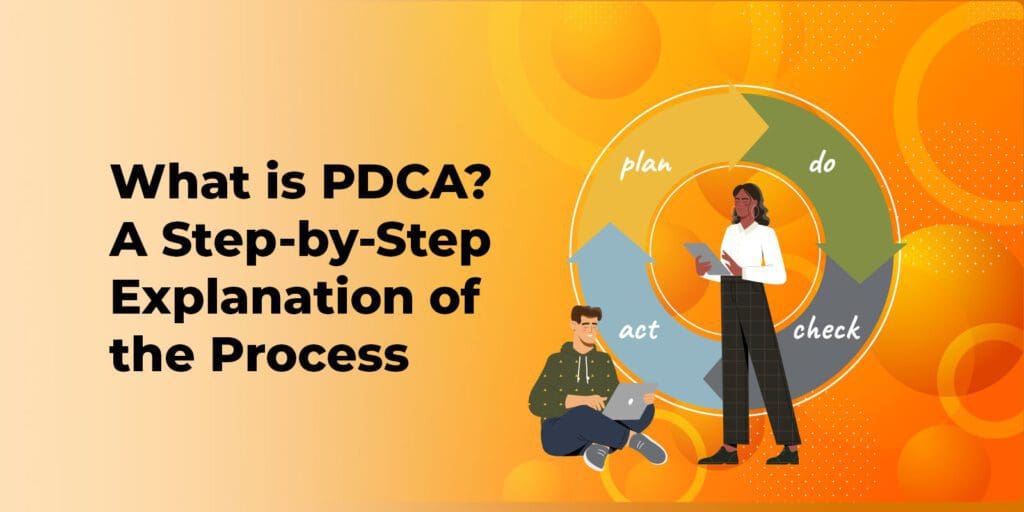

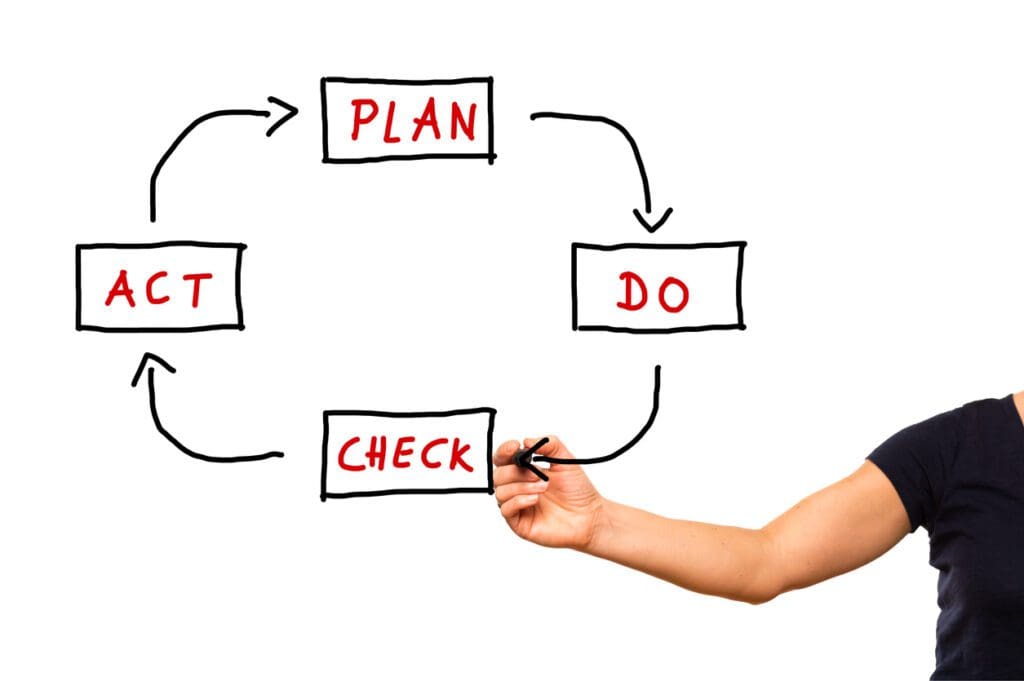

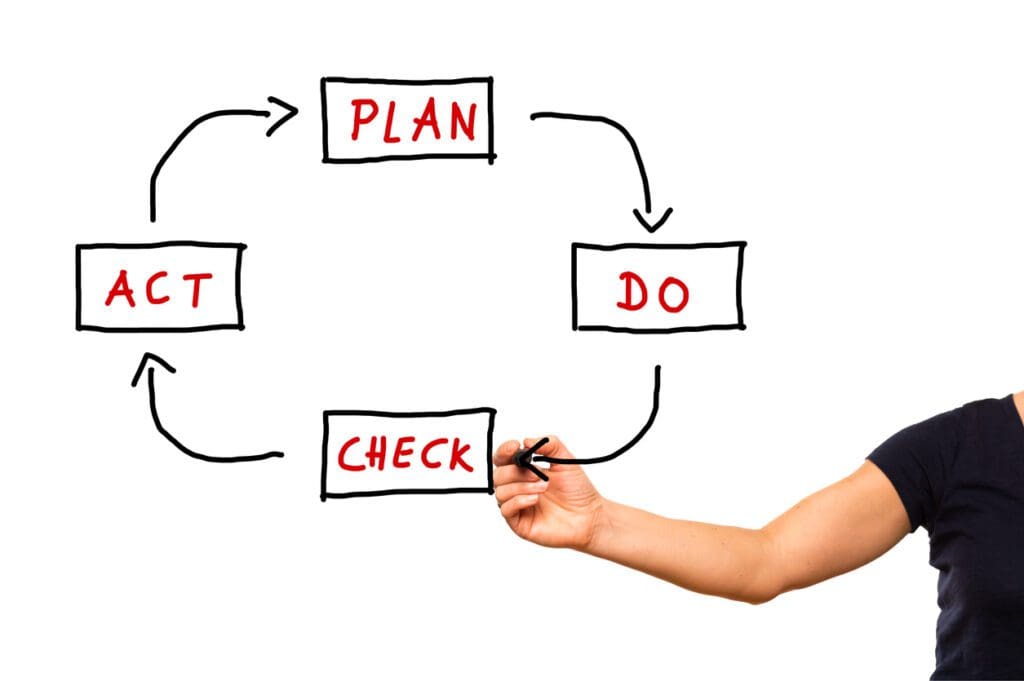

Plan, Do, Check, Act (PDCA) is an essential cycle in quality management and continuous improvement. It is a four-step model that helps individuals and organisations improve their processes and achieve their goals.

The PDCA cycle is a straightforward and efficient methodology that helps individuals and companies continuously improve their operations. It is also a useful framework for determining the root cause of defects and developing solutions that prevent them from reoccurring.

In this article, we will explore what PDCA is, its history, the PDCA model, and how it works in quality management and continuous improvement.

Introduction to PDCA

The PDCA cycle is an iterative process that helps individuals and organisations continuously improve their operations. It is a simple yet effective model that allows individuals and organisations to identify areas for improvement, implement changes, and monitor the results. The PDCA cycle is widely used in quality management and continuous improvement initiatives.

What is PDCA?

PDCA stands for Plan, Do, Check, Act. It is a four-step model used to improve processes and achieve goals. The PDCA cycle is an iterative process and a continuous improvement cycle. The Deming cycle, named after Dr W. Edwards Deming, and the Shewhart cycle, named after Walter A. Shewhart, are other names for the PDCA cycle.

The History of PDCA – Deming and Shewhart Cycles

The history of the PDCA cycle can be traced back to the work of Dr W. Edwards Deming and Walter A. Shewhart. Dr Deming was an American engineer, statistician, and business consultant most recognised for his work in Japan in the 1950s. Walter A. Shewhart was an American physicist, engineer, and statistician best known for his work in statistical quality control.

The PDCA Model – Plan, Do, Check, Act (PDCA) and Plan, Do, Study, Act (PDSA)

The PDCA cycle is a four-step paradigm for improving processes and achieving goals. Plan, Do, Check, and Act is the four steps. The Plan, Do, Study, Act (PDSA) model is another name for the PDCA methodology. The PDSA model is a variation of the PDCA model that includes the Study step.

Why is PDCA important for modern quality control?

PDCA is important for modern quality control because it is a simple and effective model that allows individuals and organisations to improve their processes continuously. The PDCA cycle is an iterative process that helps individuals and organisations identify improvement areas, implement changes, and monitor the results.

How does PDCA work in quality management and continuous improvement?

PDCA works in quality management and continuous improvement by allowing individuals and organisations to improve their processes continuously. The PDCA cycle is an iterative process that helps individuals and organisations identify improvement areas, implement changes, and monitor the results. The PDCA cycle is a straightforward and efficient methodology for helping individuals and companies continuously improve their operations.

The PDCA Process – Step-by-Step Explanation

The PDCA process is a four-step model to improve processes and achieve goals. The four steps are Plan, Do, Check, and Act. The PDCA process is an iterative process that allows individuals and organisations to improve their operations continuously.

Plan

The first step in the PDCA process is Plan. In this step, individuals and organisations identify the problem or opportunity, define the goal, develop a plan to achieve the goal and establish a baseline for measuring progress.

Do

The second step in the PDCA process is Do. In this step, individuals and organisations implement the Plan developed in the Plan step.

Check

Check is the third step in the PDCA process. In this step, individuals and organisations measure the results achieved in the Do step against the baseline established in the Plan step.

Act

The fourth step in the PDCA process is the Act. In this step, individuals and organisations take action based on the results measured in the Check step. If the results are unsatisfactory, individuals and organisations return to the Plan step to develop a new plan to achieve the goal.

How can project managers use PDCA to improve work processes?

Project managers can use PDCA to improve work processes by allowing them to improve their operations continuously. The PDCA cycle is an iterative procedure that enables project managers to discover areas for improvement, execute changes, and track the outcomes

Examples of PDCA Cycles in action

There are many examples of PDCA cycles in action. One example is a manufacturing company that uses the PDCA cycle to improve its production process. The business saw a problem with the calibre of its products and used the PDCA cycle to locate the issue’s primary cause, put fixes in place, and evaluate the results.

The benefits of using PDCA in business

The benefits of using PDCA in business are numerous. PDCA allows individuals and organisations to improve their processes, leading to increased efficiency continuously, decreased costs, and improved customer satisfaction. PDCA also enables individuals and organisations to identify areas for improvement and implement changes in a structured and systematic way.

Conclusion

The PDCA cycle is an iterative process that helps individuals and organisations seamlessly improve operations. The PDCA cycle is a straightforward and efficient methodology for helping individuals and companies continuously improve their operations. It is also a useful framework for determining the root cause of defects and developing solutions that prevent them from reoccurring.

When using PDCA, it is important to remember that no single approach is best. The best practice is using various tools and methods to achieve your goals, such as the four-step PDCA cycle. The basics of PDCA apply to any project, be it business development or engineering design, and to any organisation, be it a startup or a large, established enterprise.

Now that you know what PDCA is, you can apply this knowledge by implementing this methodology in your business operations.

Sign up for free to execute your goal-planning strategies starting today!